How Preventive Fleet Maintenance Helps You Stay Fully DOT Compliant

Explore how preventive fleet maintenance reduces violations, boosts vehicle safety, supports DOT compliance, and keeps your fleet road-ready. A proactive strategy helps prevent breakdowns, improve inspections, and ensure safer operations.

Jakob Rhiel Madsen

Nov 18, 2025Maintaining compliance with the Department of Transportation (DOT) is one of the biggest responsibilities carriers face today. Whether you operate a small fleet of trucks or manage hundreds of vehicles across multiple states, staying compliant isn’t optional—it directly impacts your safety rating, insurance costs, business reputation, and ability to stay operational.

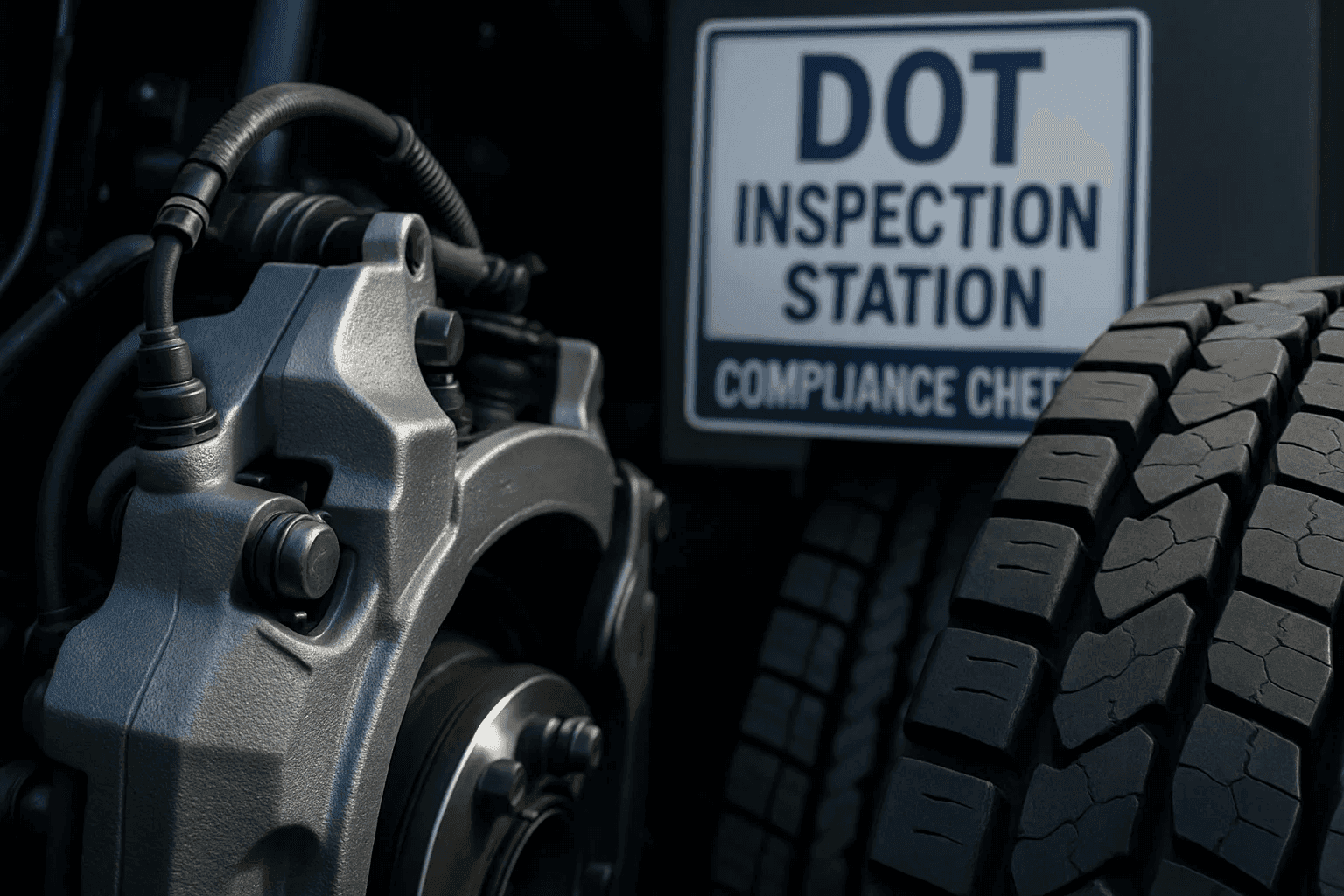

DOT compliance goes far beyond paperwork. It’s about ensuring that every vehicle on the road is safe, reliable, and properly maintained. Even a minor oversight, an underinflated tire, worn brake pads, or a malfunctioning light can result in violations, roadside breakdowns, or even preventable accidents. This is where preventive maintenance becomes a carrier’s strongest defense.

Preventive maintenance is more than routine service. It’s a strategic, proactive approach to identifying issues before they become serious, helping fleets remain safe, efficient, and fully inspection-ready.

In this blog, you’ll explore why preventive maintenance is essential for DOT compliance, which tasks matter most, and how drivers and digital systems play a critical role in keeping fleets compliant and operational.

What is Fleet Maintenance Management?

Fleet maintenance management is the process of overseeing, scheduling, and controlling all maintenance activities required to keep a fleet of commercial vehicles safe, reliable, and fully operational. It involves tracking vehicle performance, planning preventive maintenance, managing repairs, monitoring inspections, and ensuring compliance with DOT and FMCSA regulations.

Effective fleet maintenance management helps carriers reduce breakdowns, extend vehicle lifespan, and control operational costs. It also includes coordinating with drivers, mechanics, and maintenance teams to identify issues early and address them quickly. By using maintenance schedules, digital tools, and detailed records, fleets can improve safety, minimize downtime, and keep every vehicle road-ready and compliant.

Benefits of Preventive Maintenance for DOT Compliance

Preventive maintenance does far more than keep your vehicles running smoothly; it plays a crucial role in maintaining DOT compliance. When executed properly, an effective maintenance program supports every aspect of regulatory readiness and fleet safety.

Below are some of the most important benefits:

Lower CSA Scores

Your Compliance, Safety, and Accountability (CSA) score impacts everything—from insurance rates to the likelihood of being selected for inspections. Poor vehicle conditions often lead to violations that directly raise CSA scores. With preventive maintenance, fleets can ensure that key components are always within compliance thresholds, thereby strengthening safety ratings and minimizing risk.

Discover: How to Improve Your CSA Score: Proven Strategies to Avoid FMCSA Violations

Fewer Roadside Violations

Many roadside violations stem from issues that could easily be prevented through regular inspections and scheduled service. Tires, brakes, and lighting violations consistently top the list of DOT infractions. Checking and addressing these items ahead of time dramatically reduces the chances of being flagged during roadside inspections.

Reduced Downtime and Fewer Breakdowns

Unexpected breakdowns don’t just cause operational disruption—they also increase costs, put drivers at risk, and can trigger DOT scrutiny during inspections. Preventive maintenance identifies weak or failing parts early, allowing carriers to schedule repairs before failures occur, reducing downtime and keeping vehicles on the road.

Increased Driver Safety and Confidence

Safe vehicles build driver trust. When drivers know they’re operating well-maintained equipment, they feel more confident and focused. This improves driving performance and reduces stress, while also decreasing the chance of accidents linked to vehicle malfunction.

Better Insurance Rates

Insurance companies reward fleets that demonstrate strong safety performance and low incident rates. Preventive maintenance lowers the risk of costly claims, which helps fleets qualify for more favorable premiums. Additionally, a solid maintenance record shows insurers that a carrier takes safety seriously.

How Proactive Maintenance Strengthens Your DOT Compliance

One of the most important relationships in fleet operations is the connection between compliance and preventive maintenance. Preventive maintenance is the foundation of DOT readiness. By staying ahead of repairs and following a structured maintenance schedule, fleets can maintain safe, compliant vehicles that pass inspections with confidence.

Here’s how proactive maintenance supports DOT compliance:

Reducing Violations During Inspections

DOT officers often cite the same recurring issues: worn brake components, defective tires, broken lights, and suspension problems. Most of these violations are avoidable with regular maintenance. Ensuring that vehicles meet DOT inspection standards before they hit the road significantly reduces the likelihood of citations.

Keeping Vehicles Safe, Road-Ready, and Audit-Ready

DOT audits and roadside inspections require vehicles to be in top condition. When fleets follow preventive maintenance routines, equipment stays reliable and compliant throughout daily operations. Vehicles that are consistently cared for are far more likely to pass Level I, II, or III inspections without complications.

Preventing Accidents Caused by Mechanical Failures

A significant number of commercial vehicle accidents occur due to mechanical faults—many of which could have been prevented. Brake failures, tire blowouts, and steering malfunctions are among the most common. Preventive maintenance reduces these risks and helps drivers avoid dangerous on-road situations, protecting both fleet assets and public safety.

Explore: Truck Driver Safety: Best Practices for Safer, High-Performing Fleets

Key DOT Requirements Related to Fleet Maintenance

To fully understand how preventive maintenance supports compliance, carriers need to know the specific DOT requirements they’re expected to follow. These rules help maintain consistent fleet safety standards across the industry.

a. FMCSA §396 Maintenance Rules

The Federal Motor Carrier Safety Administration (FMCSA) outlines several regulations related to maintenance and inspection responsibilities.

§396.3 – General Maintenance Requirements

Carriers must systematically inspect, maintain, and repair all commercial motor vehicles under their control. This includes ensuring that parts and accessories are always in safe operating condition.

§396.11 – Driver Vehicle Inspection Reports (DVIRs)

Drivers must complete post-trip inspections, documenting any issues that could affect safety. Carriers must repair defects before the vehicle can operate again.

§396.13 – Pre-Trip Inspections

Before starting a shift, drivers must evaluate the vehicle’s condition and verify that issues reported previously have been addressed. This reinforces a two-way safety check between drivers and maintenance teams.

b. Annual DOT Inspections

Every commercial motor vehicle must undergo an annual DOT inspection. Inspectors assess key safety components such as brakes, tires, lights, steering, suspension, and exhaust systems. Vehicles should be maintained throughout the year—not just at inspection time—to ensure they pass.

c. Required Maintenance Records

Carriers must maintain detailed records for each vehicle, including:

- Inspection logs

- Repair documentation

- Parts replacements

- Maintenance history

- Records are retained for at least 12 months while the vehicle is in service

- An additional 6 months after the vehicle leaves the fleet

Accurate records serve as critical evidence during audits, demonstrating that the carrier is maintaining compliance.

The Role of Drivers in DOT-Ready Preventive Maintenance

Drivers play an essential role in maintaining compliance and vehicle safety. They are often the first to spot problems and must be properly trained to perform thorough inspections.

Importance of Accurate, Complete DVIRs

A well-documented DVIR ensures that maintenance teams address safety issues before the vehicle returns to the road. Incomplete or inaccurate reports put fleets at risk of violations and unsafe conditions.

How Drivers Detect Early Warning Signs

Drivers should be trained to notice:

- Strange noises

- Reduced braking power

- Steering instability

- Warning lights

- Unusual vibrations

- Fluid leaks

Early detection prevents small issues from becoming major risks.

Reporting Issues in Real Time

Mobile apps and digital DVIR systems help drivers report problems instantly, ensuring that maintenance teams can act quickly to correct issues.

Training to Avoid “Pencil-Whipping” Inspections

Signing off inspections without actually completing them—known as pencil-whipping—is a serious compliance risk. Ongoing training and accountability help build a safety-first culture.

Keeping Accurate Timelines

DOT requires records to be maintained for specific periods. Digital systems help carriers ensure nothing is deleted or misplaced.

Learn: Identifying High-Risk Drivers: A Key Step to Safer Roads and Effective Fleet Operations

How DQid Helps Fleets Stay Compliant with DOT Regulations

DQid is a fully integrated compliance platform designed to simplify and automate driver qualification management. Here’s how DQid helps fleets maintain DOT compliance:

Centralized, Audit-Ready Files: All driver qualification documents are stored in one secure digital hub, making it easy to access and present during DOT audits.

Proactive Expiration Tracking: The system sends real-time alerts before any document expires (e.g., CDL, medical certificates), helping you renew well in advance.

Automated Document Requests: Rather than chasing drivers for paperwork, DQid triggers automated renewal or submission requests for missing or soon-to-expire documents.

Custom Compliance Processes for Any Fleet Type: Whether you're running long-haul semis, box trucks, cargo vans, or motorcycles, DQid supports regulation workflows tailored to your fleet’s composition.

Improves CSA Scores: By keeping all driver qualification files consistently up to date, DQid helps reduce driver fitness violations, positively affecting CSA BASICs.

Time and Cost Savings: It automates record-keeping and compliance tasks, freeing up administrative time and lowering the risk (and cost) of non-compliance.

Conclusion

Preventive fleet maintenance is the backbone of DOT compliance. From lowering CSA scores to preventing roadside violations, reducing breakdowns, improving driver safety, and strengthening audit readiness, a proactive maintenance strategy benefits every part of your fleet operations.

By prioritizing regular inspections, following structured maintenance schedules, training drivers effectively, and keeping detailed records, carriers can stay fully compliant, operate more efficiently, and protect both their drivers and business.

When compliance and maintenance work hand in hand, your fleet becomes safer, more reliable, and better positioned for long-term success.

Start Empowering Your Fleet Today

Experience the power of Intelligent Compliance with a free, no-obligation demo and partner network walk-through. See firsthand how we can help you achieve higher compliance standards. Partner with us and elevate your fleet today.

Request a Demo

Join our community

Connect with industry professionals and stay updated on the latest in driver qualification management.

Stay Connected

Get industry updates, regulatory news, and safety insights sent to your inbox.